The Vibrafloor advantages

NO PERSONAL

Reclaiming by an active floor Vibrafloor is entirely automated. No personnel are required inside the silos.

TOTAL CLEAN -UP

Vibrafloor guarantees to completely empty silos, stores and ships of bulk products such as soya bean meal, wood-pellets, sugar, cereals & pulses, cotton seed, biomass and fertiliser automatically and without human intervention. Thus issues of residual product causing fires or solidifying to create maintenance problems and risks to personnel are avoided.

HIGH RECLAIM RATES

Vibrafloor operates on demand triggered by sensors within the silo being uncovered. Depending on the size, design and profile of the silo or store, the reclaim rate may range from a few hundred kilos to many thousands of tonnes per hour.

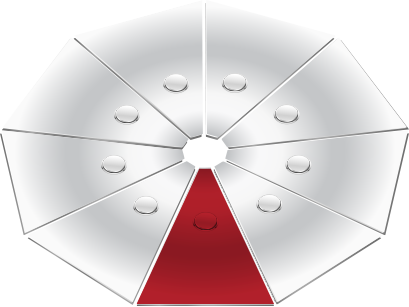

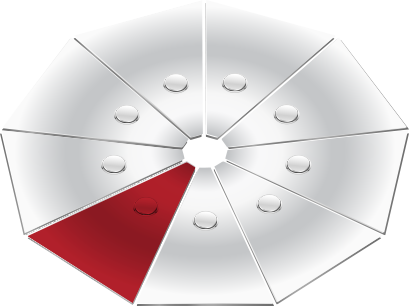

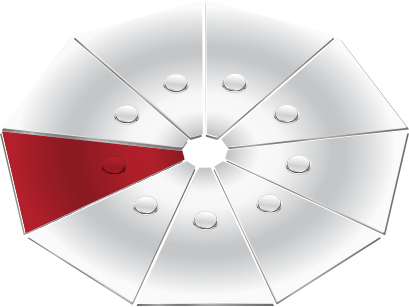

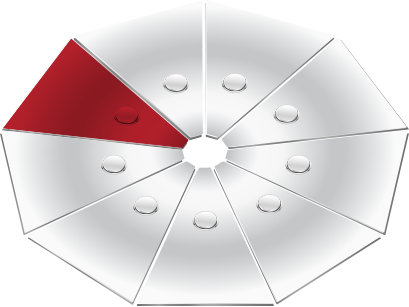

AUTOMATION

The PLC ON/OFF signal initiates groups of vibrators which are triggered sequentially by capacitive sensors. The system stops itself when empty by material detection. A clean-up operation is entirely controlled by an ON/OFF signal from the control room.

NO DUST CLOUD

A clean-up operation by active floor Vibrafloor does not generate dust clouds, this limits the explosion risk of sensitive materials. Video films are currently shot inside silos in operation.

No Damaging Vibration or Stress Transfer

All vibrating parts of a Vibrafloor rest on a bed of coil springs, and are kept in place by a thermoplastic membrane. Therefore no significant vibration energy is transferred into the structures, which can be concrete silos, corrugated steel silos, ships, railway cars, containers etc…

Vibrafloor does not transfer any damaging stress or torque to the silo structure. All but harmless residual vibration is isolated within the body of each module, avoiding the unnecessary expense of reinforcing lightweight silos and store.

TOTAL SAFETY

The Module design complies with all ATEX Safety rules for zone 21. Personnel safety is total as clean-up by Vibrafloor requires no human intervention. Structures do not incur any damage on account of vibrations and fragile products are not degraded by the reclaiming process.

LOW ENERGY CONSUMPTION

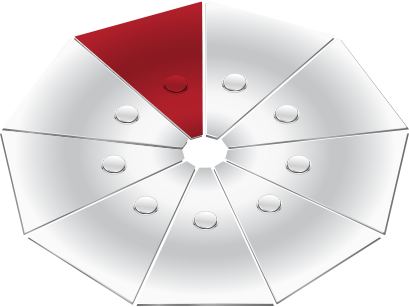

Vibrafloor consumes very little energy compared to other mechanical bulk reclaim technologies. Each vibrating motor is 690W installed capacity but only the exposed modules in the low pressure zone are triggered at one time.

NO ROUTINE MAINTENANCE

Vibrafloor requires no routine maintenance other than regular visual inspection. There are no major rotating or wearing parts within the Vibrafloor system, other than the vibrator motors which are isolated from the product beneath the domed motor-covers.